How We Manufacture The Best Quality Products

In past forty years, we have gained extensive knowledge in food production, which is why P Mark stands for offering top-quality food products. Our highly skilled team is able to identify quality ingredients because of the latest testing equipment we use. The ingredients are thoroughly checked for damage such as infestation, grittiness, insects, fungus infection, dirt, plant debris, and other impurities.

step

01

pre-cleaning

-

Impurities in the ingredients are cleaned intensively with high-efficiency and accuracy using the modern machines and damaged particles are also separated.

-

Food safety is one of our prime most objectives and we continuously strive to keep ahead of the ever-increasing food safety standards.

step

02

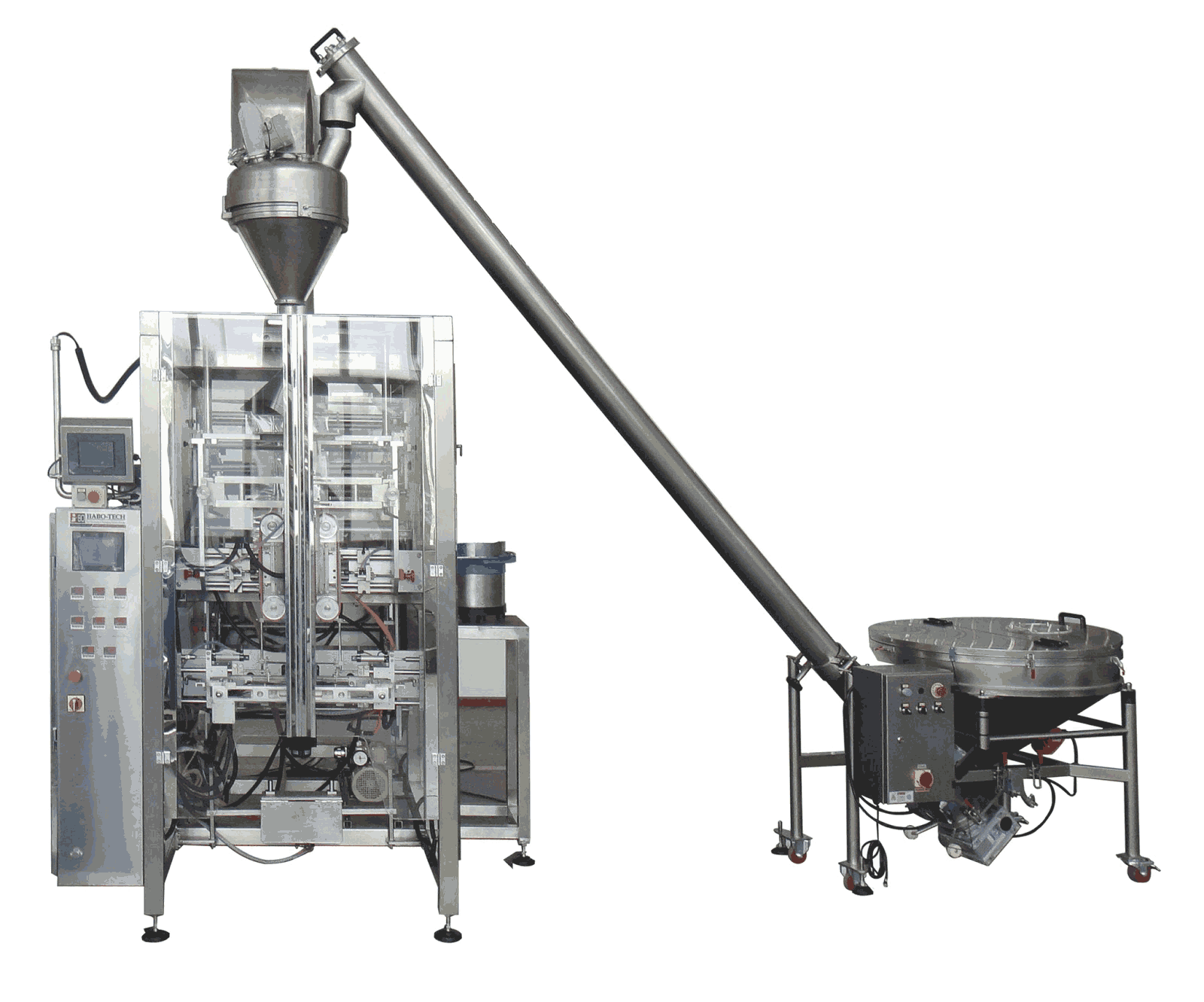

milling

-

We use state-of-the-art milling technology to ensure sanitation, and product safety.

-

We use the latest steel plansifters that use metal sieve frames, also used by top manufacturers of the USA and Europe to ensure excellent sanitation of P Mark food products in the market; whereas local Mills use wooden plansifters, which are prone to infection, and insects.

step

03

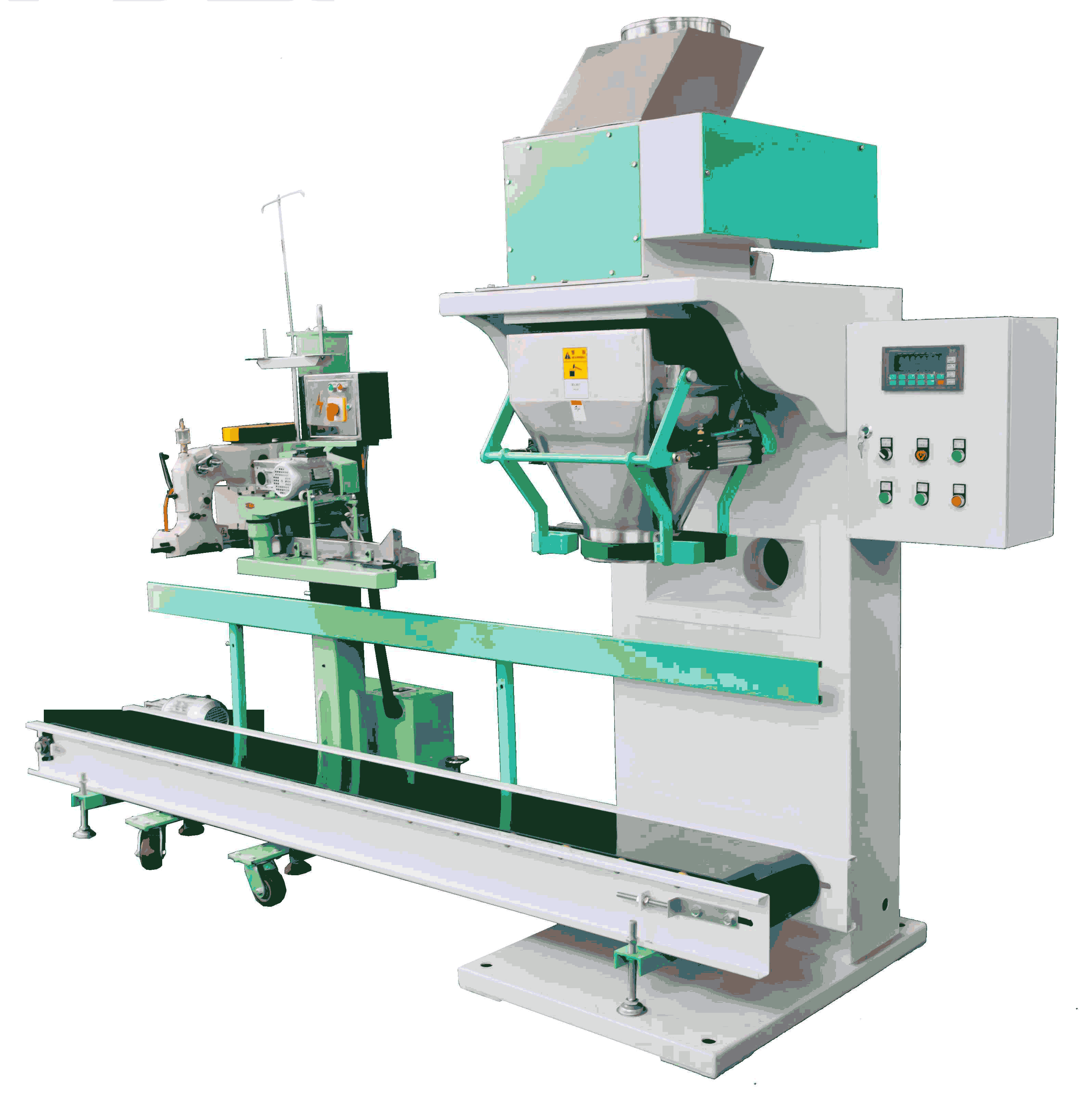

Weighing & Packing

-

Our packaging process is free of human touch & foreign contamination as we use fully automated bagging system.

-

Essential mineral and vitamins need to mix with the help of high precision instruments & for that we have high precision micro feeders

step

04

Quality Testing & Dispatch

-

We never compromise when it comes to food safety & quality. P Mark has a highly advanced and fully equipped food-testing laboratory with the technical assistance of CFTRI, Mysore.

-

The laboratory monitors the quality of raw material and finished products to ensure the highest level of food standards—unparalleled and incomparable quality.

our customers